|

|

|

|

Tank Components Tank Components

|

ISO TANK CONTAINER ISO TANK CONTAINER |

|

ISO TANK CONTAINER is a pressure vessel mounted in a frame. Frame dimensions comply with the recommendations of the International Standards Organization(ISO). The unit is designed and constructed in accordance with strict international codes for the worldwide carriage of bulk liquids on land, rail and water. |

|

|

ISO tank construction materials are made of stainless steel AISI 316.

Tanks are classified according to the specifications of tank shell and fittings.

It is this classification that determines what type of product may be carried. |

|

|

STRUCTURE STRUCTURE |

|

ISO tank consists of a single, cylindrical vessel (the tank body) within a rectangular steel framwork. The frame is built according to International Standards Organization(ISO) specifications.

The typical container length is 6,058mm, standard width is 2,438mm and height is 2,591mm. The frame design must meet strict standards, including stacking, longitudinal and lateral inertia. The tank design, which varies according to the commodity and customer's specification, must also meet specified requirements. These standards are determined by a number of national and international government agencies. The weight of an empty tank container generally varies between 3000 and 5000 kg. |

Tank body Tank body |

|

The tank body is usually built from stainless steel, carbon steel or aluminium and has one or more loading openings at the top (manholes), and usually one central discharge opening at the bottom.

Safety valves avoid excessive pressure build up inside the tank shell, whilst triple closures (a combination of a foot valve, a product valve and a drip cap) avoid undesirable leakages of the loaded product during transit. Tank containers are usually discharged using ordinary air pressure (average pressure of 2 bar) to push out the loaded product.

Products with high flashpoints are discharged using a pump, whilst vapour return lines are used to avoid any air contamination during the loading and discharge process. Many tanks are insulated by a variety of materials to maintain the temperature of the carried product.

|

|

|

THE FRAME THE FRAME |

|

The function of the frame is to support and protect the tank as well as to facilitate the stowage, securement and handling by standard ISO container recommendations. |

|

|

The standard dimensions are 6,058mm X 2,438mm X 2591mm. |

|

|

Details Details |

|

Generally, a tank container consists of two main sections: the frame and the cylindrical barrel made of stainless steel. However, each tank also has several additional features. The features vary from one tank container to another, below we give you some examples of features. |

|

|

On top of the tank container, you can find a walkway.

To get on top of the tank, there is also a ladder at the back of the container. Many tank containers also have a dipstick in stainless steel and a properly engraved calibration chart. The chart enables you to calculate the volume of the product to be loaded, expressed in liters. The dipstick gives a visual check on the actual volume that has been loaded into the tank container.

Two other standard features are the document-tube and the label holder. The document-tube should be watertight and of sufficient size to contain all the necessary load documentation. It should be located in a protected and secured area to avoid document theft during transit, a recognized problem within the industry. The label holder is secured to the tank shell, and displays the safety labels required to identify the tank contents. Well-equipped tank containers have several label holders.

The tank container also has an identification plate or certificate plate, with general information on technicalities and origin of the tank. |

|

|

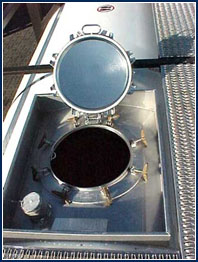

| ① Manlids |

|

The manlids cover the loading manholes on top of the tank container.

Each manlid has 6 tightening clamps with swingbolts. The insulated manlid covers avoid loss of temperature. They also offer space to carry sample bottles,

and keep the loading area clean and well protected.

Anti slip zones inside the manlid covers increase the operational safety. |

|

|

|

|